How to Choose the Right Warehouse Lighting Solution?

By Johnny Updated: Nov 11, 2024

Table of Contents

1.Introduction

2.Major Challenges of Warehouse Lighting

3.Types of Traditional Warehouse Lighting and Their Drawbacks

4.Why Choose LED Lighting

5.Types of LED Warehouse Lighting

6.LED Warehouse Lighting Recommendations by Location

7.How to Choose the Right LED Warehouse Lighting

8. FAQ

9.Conclusion

1. Introduction

In today’s digital world, warehouses are busier than ever with the rise of online shopping. Lighting can

make up a big part of a warehouse’s energy costs, so it needs to be efficient and cost-effective,

especially for 24/7 operations. Long-lasting, energy-efficient LED lighting can significantly lower costs

by reducing downtime and energy use, while also improving safety. In this guide, we’ll look at how

upgrading to LED lighting can boost performance, cut costs, and create a safer workspace.

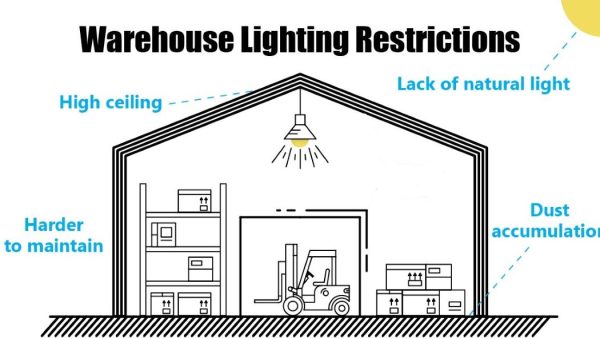

2. Major Challenges of Warehouse Lighting

Warehouses are vast spaces with high ceilings, which present unique lighting challenges.

Here are some common issues:

Large space, high ceilings: Traditional lights struggle to provide uniform illumination across expansive

areas. You need stronger, more focused lighting.

High lighting costs: Meeting these lighting needs with traditional systems often results in enormous energy bills.

Environmental demands: Warehouses can be dusty, humid, or exposed to harsh conditions. The lights need to

be durable—dustproof, waterproof, and long-lasting.

Difficult Maintenance: Due to the height, changing a bulb isn’t as simple as using a ladder; it often requires lifts

or specialized equipment, adding time and cost. For 24/7 operations, even a short maintenance break can impact

efficiency.

3. Types of Traditional Warehouse Lighting and Their Drawbacks

Let’s look at the common traditional lighting options and their limitations.

Metal Halide Lights

Cons: High energy consumption, slow start-up, short lifespan, frequent replacements, leading to high maintenance costs.

High-Pressure Sodium Lamps

Cons: Yellowish light, poor color rendering, making it harder for workers to see clearly and reducing productivity.

Fluorescent Lights

Cons: Shorter lifespan compared to LEDs and contains mercury, which is not environmentally friendly.

4. Why Choose LED Lighting?

LEDs have transformed warehouse lighting in recent years. Here’s why:

Energy efficiency: LEDs consume 50% less energy than traditional lighting options, significantly

reducing your electricity bill.

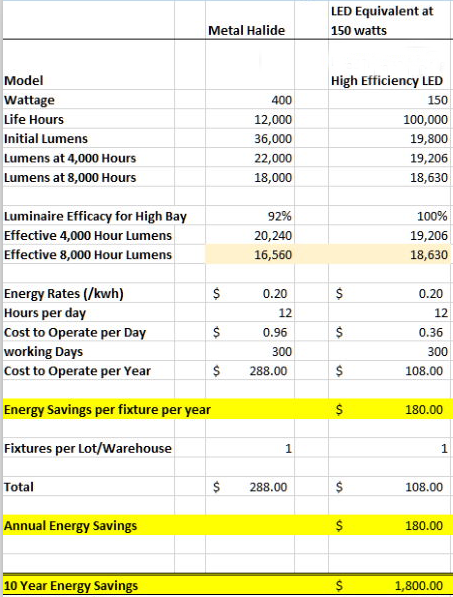

1pcs 150W LED UFO high bay replacing 400W Metal Halide, if works 12hrs/day 300days/year,

it saves: 900kw/year, 62.5%, 180$/year

Before(400W Metal halide light) After(150W LED UFO high bay)

Long lifespan: LEDs last up to 50,000 hours or more, reducing the need for replacements and lowering

maintenance costs.

Instant lighting: No need to wait for lights to warm up—LEDs provide full brightness immediately.

Environmentally friendly: LEDs don’t contain harmful chemicals like mercury, making them a safer

choice for your business and the planet.

5. Types of Warehouse LED Lighting

Common LED lighting solutions include LED UFO High Bay Lights, Linear High Bay Lights, Tri-proof Lights, and Tube Lights.

Among these, UFO High Bay and Linear High Bay are the top choices for high-ceiling areas.

UFO High Bay Lights are circular, compact, and easy to install, even in tight spaces. They typically feature a wide beam

angle, making them ideal for large, open areas where uniform light distribution is essential.

Linear High Bay Lights offer a rectangular beam pattern, which is particularly effective for warehouse aisles and other rectangular spaces. This design provides consistent lighting along the length of the space, ensuring greater coverage

for aisle-based layouts.

LED UFO High Bay Lights

Our LED UFO High Bay lights are good choices. (100/150/200/250/300/400/500W 150/180LM/W)

LED Linear High Bay Lights:

Our LED Linear High Bay are good choices. (60/120/180/240/300/360/420W 140/160LM/W)

With several optical lens, LED linear light fixtures can meet all the requirements to handle various tasks

in warehouse. It helps people work precisely to increase operation efficiency and triple save energy in

applications.

LED Tri-proof Lights: Resistant to water, dust, and corrosion, perfect for harsh environments.

Our LED Tri-proof Light are good choices. (18/36/50W 130/150LM/W)

LED Tube Lights: Great for lower ceilings or as supplementary lighting.

Our LED tube lights are good choices. (1.2/1.5m 18/25W 120/140/160 LM/W)

Emergency Lighting: Essential for maintaining safety during power outages.

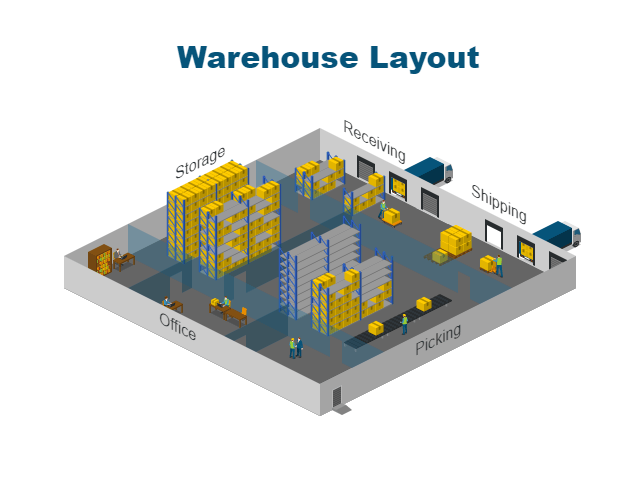

6. LED Warehouse Lighting Recommendations by Location

Warehouse Interior Areas

Receiving Area

Lighting Requirement: Requires bright, even lighting to ensure incoming items are clearly visible.

Recommended lights: LED UFO & linear high bay, which provide high brightness and broad coverage.

Storage Area

Lighting Requirement: Needs good visibility throughout the storage area to avoid shadows.

Recommended lights: LED linear high bay, suitable for high-rack areas, providing uniform illumination.

Picking Area

Lighting Requirement: Requires bright light to quickly and accurately locate items.

Recommended lights: LED linear lights and tube lights, offering high efficacy and ideal for long aisle picking areas.

Packing Area

Lighting Requirement: Needs bright, wide-area lighting to facilitate detailed packing and labeling work.

Recommended lights: LED tri-proof lights, suited for dusty and humid environments, ensuring safety and durability.

Aisles and Walkways

Lighting Requirement: Requires moderate lighting to ensure personnel safety and avoid accidents.

Recommended lights: LED wall lights or ceiling lights to provide adequate illumination.

Office and Rest Areas

Lighting Requirement: Requires soft, comfortable lighting to create a pleasant work and rest environment.

Recommended lights: LED panel and tube lights, providing uniform lighting.

Emergency Exits and Safety Areas

Lighting Requirement: Must be visible in emergencies to avoid dark areas.

Recommended lights: LED emergency lights to ensure safety

Warehouse Exterior Areas

Parking Lot

Lighting Requirement: Ensure the safety of vehicles and pedestrians, avoiding potential accidents.

Recommended lights: LED street lights or floodlight, as they provide intense illumination in a relatively compact package,

and are easy to mount on poles or mounting surfaces.

Shiping area (Loading and Unloading Dock)

Lighting Requirement: Requires sufficient illumination to ensure safety during nighttime loading and handling.

Recommended lights: LED floodlights to cover large areas and ensure brightness in operational zones.

7. How to Choose the Right LED Warehouse Lighting

Choosing the right LED lighting for warehouse involves several factors. Here are six key features to consider:

1) Wattage, Lumen

The right brightness for a warehouse depends on the space application scenario. Find the recommended

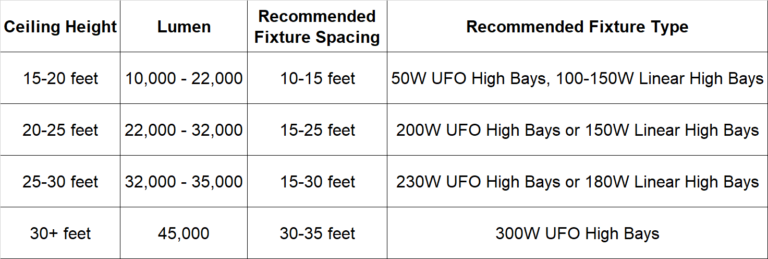

lumen and recommended fixture according to the ceiling height in the chart below:

When Replace Traditional Lighting with LEDs, for example:

- Metal Halide 400W ≈ LED 150W

- High-Pressure Sodium 250W ≈ LED 100W

- Fluorescent 4 x 36W ≈ LED tube 4 x 18W

2) Lux

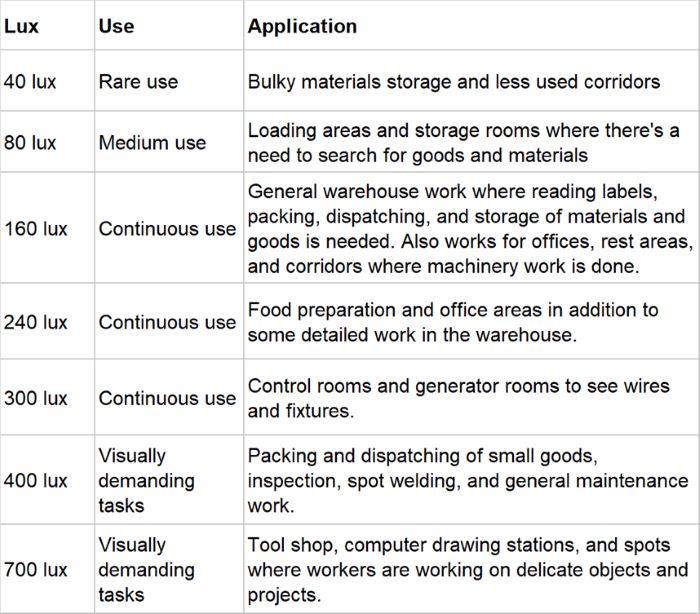

Deciding on the lux levels for the warehouse lighting system depends on the specific use of each space.

Here are common lux levels and their application:

3) Color Temperature(CCT)

Measured in Kelvins, color temperature indicates the light’s hue. For warehouses, lights between 3000K (warm yellow)

and 6000K (cool white) are ideal.

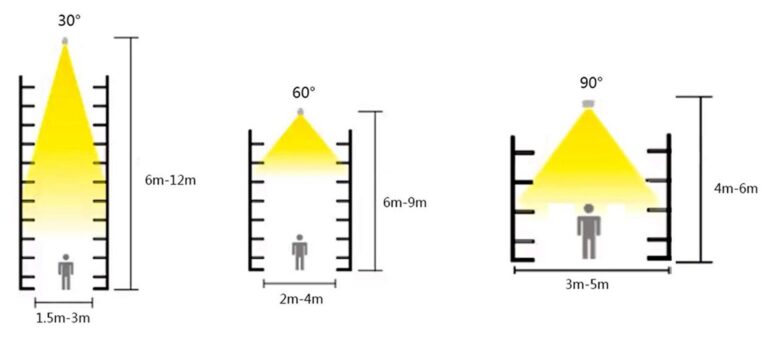

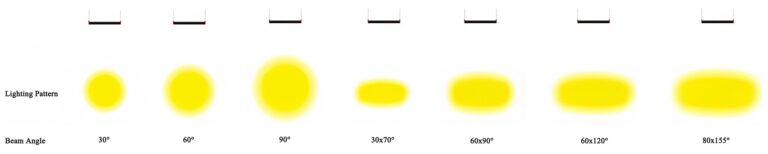

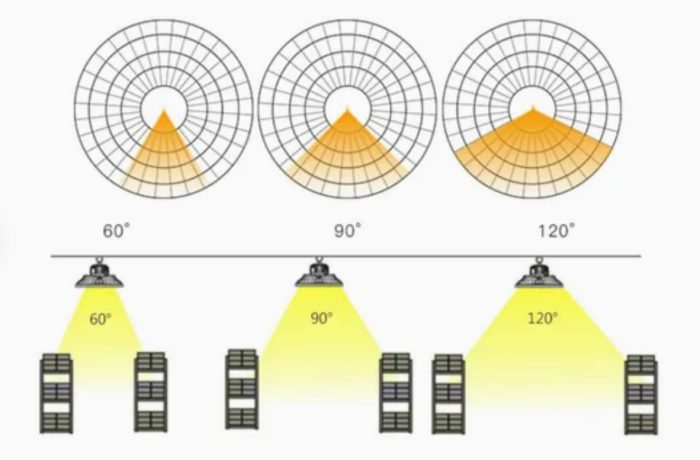

4) Beam Angle

The beam angle shows how light spreads. Wider angles are better for open areas, while narrower angles work for specific

spots like entryways.

LED Linear High Bay Light Distribution

LED UFO High Bay Light Distribution

5) CRI

Color Rendering Index (CRI) measures how well a light shows natural colors. Most warehouses will be fine with CRI 70

LED Lights. However, in a setting where color differentiation is an important part of everyday tasks, higher CRI 80-95 is

needed.

6) IP Rating

IP rating indicates the level of protection against dust and water.

For outdoor installations, an IP65 or higher rating is recommended to withstand rain and dust. Indoor usually use

can have lower IP ratings, but in some special areas like cold storage, it is necessary to use IP65 LED tri-proof lights

to prevent moisture and dust ingress.

9. FAQ

Q1: What are the main types of LED warehouse lighting solutions?

A: Common lighting solutions include LED UFO High Bay Lights, Linear High Bay Lights, Tri-proof Lights, and Tube Lights.

Among these, UFO High Bay and Linear High Bay are the top choices for high-ceiling areas.

Q2: What’s the ideal color temperature for warehouse lighting?

A: A neutral white (4000K-5000K) is typically recommended. It provides bright, clear visibility without being overly harsh,

which is ideal for productivity and safety.

Q3: How do I calculate how many LED lights I need?

A: You can use lighting design software or consult with your supplier to create an optimal lighting plan based on your

space’s size, ceiling height, and layout.

Q4: Should I use motion sensors or timers in my warehouse lighting system?

A: Yes, using motion sensors or timers is a smart choice. They automatically turn lights on or off based on occupancy,

which reduces energy waste in low-traffic areas and optimizes efficiency.

Q5: What’s the recommended brightness level for warehouses?

A: For general areas, 150 lux (brightness measure) is common, while more detailed work areas may require up to 500 lux.

Specific needs depend on tasks, with safety and visibility as top priorities.

Q6: What maintenance do LED lights require?

A: LED lights are low-maintenance compared to traditional lighting. Typically, they need occasional cleaning to remove

dust or debris, but their long lifespan reduces the frequency of replacements.

Q7: Are there any tax benefits or incentives for upgrading to LED lighting?

A: Many governments offer incentives, rebates, or tax deductions for switching to energy-efficient lighting solutions.

It’s worth checking local programs to see what benefits may apply.

Q8: What’s the difference between lumens and wattage?

A: Lumens measure the brightness a light emits, while wattage measures the energy it consumes. LED lights provide

higher lumens per watt than traditional lighting, making them both brighter and more energy-efficient.

Q9: How do I find a reliable LED lighting supplier?

A: Look for suppliers with a strong track record, clear warranty policies, and good reviews from businesses similar to

yours. Quality certifications and prompt customer support are also signs of reliability.

10. Conclusion

Choosing the right warehouse lighting can significantly impact your project by reducing costs, improving safety,

and boosting productivity. Upgrading to LED lighting is an investment that pays off in the long run. With the right

supplier, you can make the transition smoothly and start enjoying the benefits immediately.

Ready to make the switch? Explore our LED lighting solutions and see how they can transform your operations.

Request A Quote for Your Lighting Projects!

What you need is a true veteran of the LED lighting industry. Let Reapway.com help you become No.1 in the field.

About Author

Johnny Chen

Co-founder of Reapway Technology Limited, with 15 years of LED industry experience,

I specialize in market analysis, product knowledge, and team leadership. I’ve led a team

to $8 million in sales, and helped over 80 clients boost revenueby $1.2 million yearly.

And the purpose of this article is to share the knowledge related to LED linear high bay from

a Chinese supplier’s perspective.

You made several good points there. I did a search on the subject and found mainly people will have the same opinion with your blog.

Thank you

Thank you for enjoying our article!

We regularly publish new content,feel free to follow our website for more updates and explore our LED lighting products.

Thanks!

Johnny Chen

Reapway Technology Limited

Email: sales@reapway.com

Whatsapp: 0086-13728928716

Website: http://www.reapway.com

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7034

thank you.