Guide to Warehouse Lighting

By Johnny Updated: Apr 10, 2023

What is warehouse Lighting?

Lights used in warehouses and industrial buildings are often referred to as warehouse lighting, these buildings have high ceilings, high shelving, few windows, and large floor surfaces.

Choose the Right Warehouse Lighting

Warehouse lighting should achieve two things: enhance safety and increase productivity. The common industry accidents are trips,falls and slips.Having good warehouse lighting is the best way to reduce the risk of accidents.

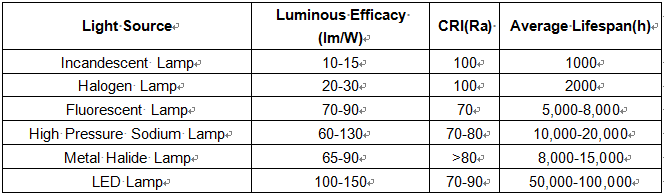

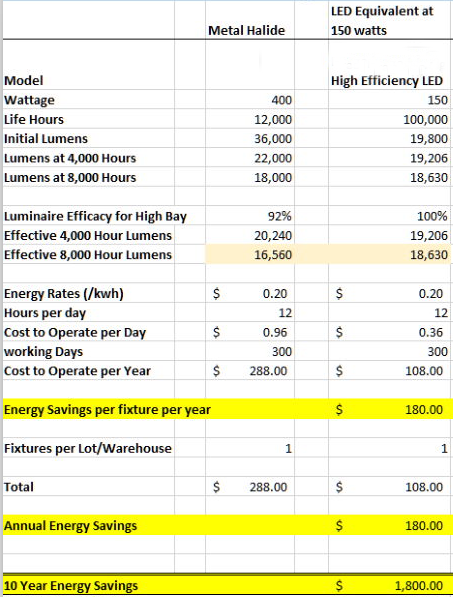

There are mainly 3 options for warehouse lighting:Metal halid lights,fluorescent lights and LED lights. LED lights are the best option as its 4 most obvious advantages as below:

1. Energy Savings Up to 60%

1PCS 150W LED UFO high bay replacing 400W Metal Halide 12hrs/day 300days/year

Saving 900kw/year saving 62.5% Saving 180$/year

Before(400W Metal halide light) After(150W LED UFO high bay)

2. Reduced Maintenance Costs

Ceiling height result in significant maintenance costs. Changing a simple light bulb often involves an elaborate process, that is quite costly in both time and money. LED lights have a long lifespan of 50,000 to 100,000 hours, the maintenance can be reduced by 90%.

3. Easily Adaptable

LED lights are physically small and easily adaptable in a range of lighting applications, can also be dimmed and provide dynamic control of light, color, and distribution.

4. Enhances Workers’ Productivity

LED lights provide a brighter, better light that increases productivity and reduces workplace accidents.

Steps to Choosing the Best LED Warehouse Lighting

1. What type of Warehouse LED Lights Do I Need?

LED UFO and Linear High Bays are two of the most common types of warehouse lighting.

LED UFO High Bay designed to replace both low & high bay HIDs, Metal Halide fixtures, and High-Pressure Sodium high bays.They’re smaller and more compact than their linear fixture counterparts.

Our 150/170/190LM/W LED UFO High Bay are good choices.

LED Linear High Bay is to replace T5 and T8 tube-style fluorescent high bays and fixtures. These high bay lights have a low profile and offer great light distribution.They’re IP66 waterproof and can work in wet locations.

Our Multifunctional LED Linear High Bay are good choices.

2. What wattage and lumens do I need to replace Metal Halide or Fluorescent Lights?

Use lumens not watts, general guidelines for converting to LED wattage:

400 watts metal halide was used most widely because of its highly popular size point, and an equivalent LED lamp

will use between 150 to 200W to produce comparable brightness. Some higher ceiling warehouses use 1000W metal halide lamp and its LED counterpart uses under 500W.

250 Watt Metal Halide, you should choose the LED lights with 10,000 to 12,000 Lumens

400 Watt Metal Halide, you should choose the LED lights with 15,000 to 25,000 Lumens

1000 Watt Metal Halide, you should choose the LED lights with 36,000 to 55,000Lumens

4 Linear fluorescent fixture comprised of 4pcs 58W T8 lamps, you should choose the LED lights with 10,000 to 15,000 Lumens

6 Linear fluorescent fixture comprised of 6pcs 58W T8 lamps, you should choose the LED lights with 15,000 to 25,000 Lumens

8 Linear fluorescent fixture comprised of 8pcs 58W T8 lamps, you should choose the LED lights with 25,000 to 35,000 Lumens

(Source: EC Directive 2005/32/EC )