4: TST Warehousing’s Lighting Transformation –Doubling Illumination and Cutting Energy Costs by 52%

1) Introduction

I’d like to show you how TST Warehousing in Kuala Lumpur, Malaysia, successfully upgraded their 3500m² warehouse

by replacing outdated lighting with Reapway super thin LED linear high bay lights. This change not only doubled their

illumination levels but also reduced their energy consumption by an impressive 52%.

In this case study, I’ll walk you through the entire process step-by-step.

2) Setting the Scene

TST Warehousing faced a significant challenge in their electronics storage area. Before the renovation, they relied on

250W 80LM/W Metal Halide lamps, resulting in uneven lighting and high energy consumption, with an average

illumination of just 50lux.

These issues affected both worker efficiency and overall operational costs, prompting TST to seek a more effective

lighting solution.

3) Results Overview

TST Warehousing made the switch to Reapway 120W 140LM/W LED linear high bay, and the impact was immediate

and dramatic. The average illumination was doubled to 150lux, vastly improving the working environment.

Additionally, energy consumption reduced by 52%, leading to annual electricity savings of 91,104 kWh and $11,934.624 in costs.

Here’s how TST achieved these remarkable results:

1: Illumination doubled to 150lux by LED, working environment was

more comfortable and operating efficiency was significantly improved.

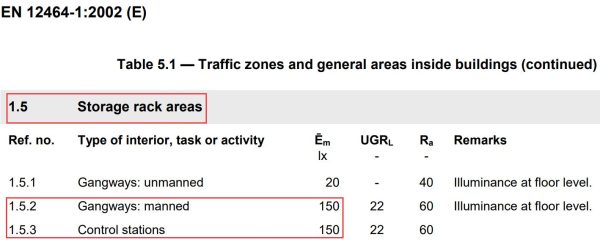

150lux for storage rack areas

2: Electricity saving 52% by LEDs.

3: Total annual electricity savings by LEDs is 91,104kwh and $11934.624.

4: LED lights provided uniform lighting across the entire shelving area,

eliminating blind spots and enhancing worker safety.

4) How It Was Done

TST Warehousing’s journey began by recognizing the limitations of their existing lighting system. The first step

was to assess the current situation, identifying areas with poor illumination and high energy usage.

After careful consideration, Reapway 120W LED linear high bay were selected for their superior brightness

and energy efficiency.

The LED lights provided uniform lighting across the entire shelving area, eliminating blind spots and enhancing

worker safety. The new lighting not only improved visibility but also created a more comfortable and productive

environment for employees, leading to better overall efficiency.

5) Customer Reviews

TST Warehousing Project Manager, Razak bin Osman: “The LED linear high bay lights have truly transformed

our warehouse operations in Kuala Lumpur. The uniform lighting eliminates any blind spots, significantly

boosting our efficiency. We’re impressed with their energy-saving capabilities and durability, which have

helped us cut down on operational costs. The installation was hassle-free, and maintenance is minimal,

ensuring a great return on investment.”

6) Conclusion

In summary, TST Warehousing successfully transformed their lighting system, achieving double the

illumination and reducing energy consumption by 52%. This case demonstrates that with the right

lighting solution, any warehouse can enhance its operational efficiency and significantly cut costs.

You can achieve similar results by making the switch to Reapway LED lights.

If this case study inspired you, consider upgrading your warehouse lighting and start reaping the benefits today.