The Ultimate Guide to Replacing Fluorescent Tubes

By Johnny Updated: May 24, 2024

Everyone knows that buying a 4ft LED tube is cheaper than replacing the entire fixture. So generally we will choose to

replace fluorescent tubes with LED tubes instead of replacing the entire tube fixture. In this article, we will tell you how

to replace fluorescent tubes with LED tubes.

Table of Contents

1.Benefits of LED Tubes Over Fluorescent Tubes

2.Understanding Fluorescent Tubes

2.1 How Fluorescent Tubes Work

2.2 Common Types of Fluorescent Tubes

3.Introduction of LED Tube

3.1 Type of LED Tube

3.2 Types of LED Replacements

4.Preparation for Replacement

4.1 Safety Precautions

4.2 Tools and Materials Needed

4.3 Understanding Wiring Configurations

5 Step-by-Step Replacement Guide

5.1 Type 1: Work with AC230V directly

5.2 Type 2: Work with magnetic ballast

5.3 Type 3: Work with electronic ballast

6.Troubleshooting Common Issues

7.FAQ

8.Expert Tips and Advice

9. Conclusion

1. Benefits of LED Tubes Over Fluorescent Tubes

Switching from fluorescent tubes to LED tubes offers numerous advantages, backed by data:

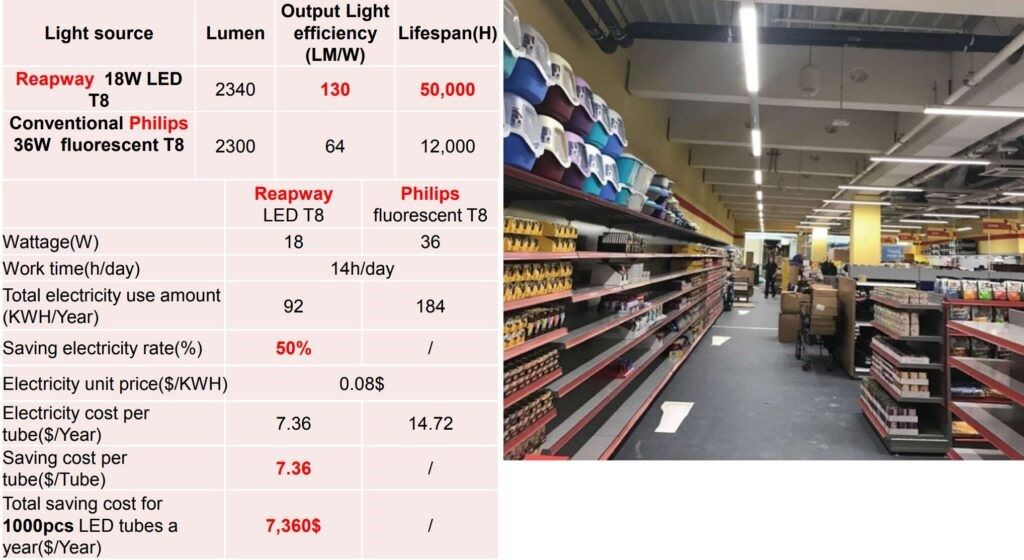

Energy Efficiency Up to 50%:

LED tubes consume less energy, using up to 50% less power than fluorescent tubes.

For example, our Reapway 18W 130LM/W LED T8 VS Conventional Philips 1.2M 36W fluorescent T8,

1000pcs Reapway 18W LED T8 for a shopping mall project:

1: Save 92,000KWH electricity a year and 50% electricity

2: Save electricity cost 7,360$/year

3: Improve 3 times lifespan

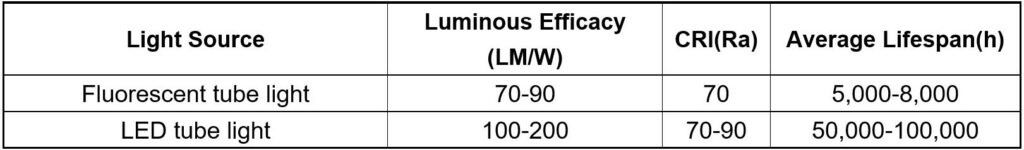

Longer Lifespan: LED tube last up to 100,000 hours, compared to 8,000 hours of fluorescent tubes.

This means an LED tube can last over 10 years if used for 12 hours a day, significantly reducing replacement frequency.

Cost Savings: On average, switching to LED tubes can save around $100-$150 per tube over its lifespan,

considering both energy and maintenance costs.

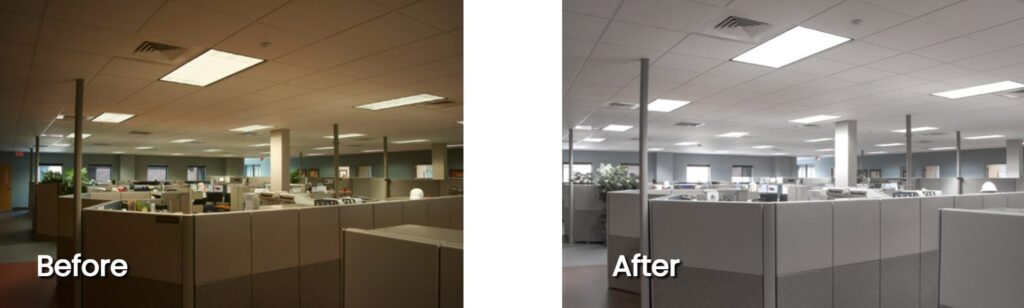

Better Light Quality: LEDs provide brighter, more consistent lighting with various color temperatures,improving

visual comfort. Studies show that LEDs can improve productivity by 5-10% in work environments due to better

lighting quality.

Instant Illumination: LEDs offer immediate, flicker-free light without warm-up time. This can enhance safety

and productivity, particularly in environments where consistent lighting is crucial.

Environmental Impact: LEDs are free of hazardous materials like mercury, making them safer for the environment.

Each LED tube can prevent the release of approximately 5 milligrams of mercury, which is typically found in a fluorescent tube.

Durability: LED tubes are more robust and resistant to shocks, vibrations, and impacts. This makes them suitable for

industrial and high-vibration environments, reducing the risk of breakage and the need for replacements.

Versatility and Compatibility: LED tubes come in various configurations (magnetic&electronic ballast compatible)

compatible with existing fixtures, simplifying the replacement process.

Directional Lighting: Fluorescent tube emits light at an angle of 360°, and the reflected light from the lamp panel

will reduce by 20-30%. The LED tube emits light at an angle of 120°, and the light loss after reflection is very small.

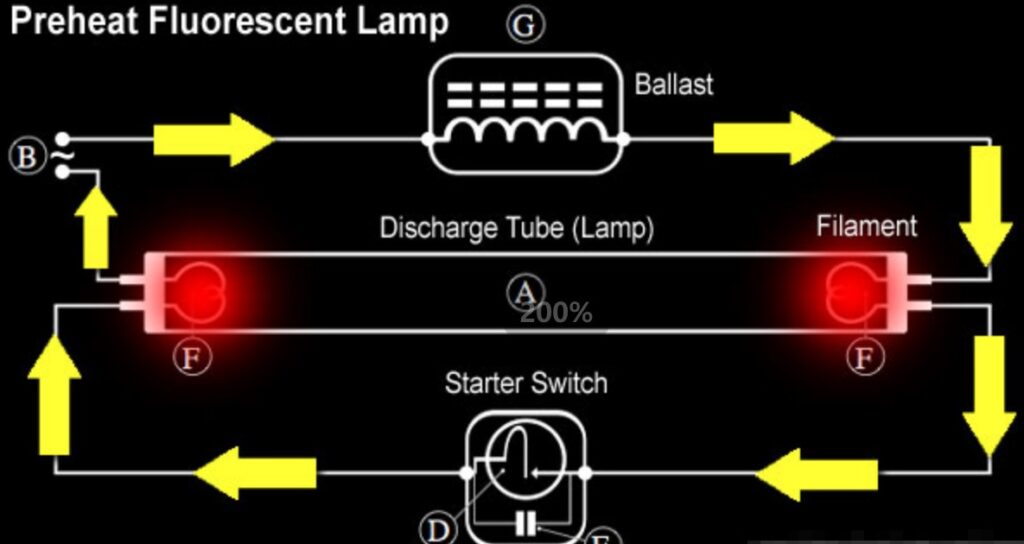

2. Understanding How Fluorescent Tubes Work

The working principle of fluorescent tubes involves current passing through a ballast and starter to start the filament

to emit electrons.

A high-voltage pulse ionizes the mercury vapor in the tube to produce ultraviolet light. The ultraviolet light illuminates

the phosphor to emit visible light. The ballast ensures stable current and maintains the normal operation of the lamp.

Double-ended power input has obvious advantages in terms of starting voltage requirements and ease of installation

and maintenance, making it the standard design for fluorescent tubes. However, single-ended power input is rarely

used in fluorescent tube due to its lack of startup and operating stability.

3. Introduction of LED Tubes

3.1 Types of LED Tubes

T8 LED Tubes: Most common,these have a diameter of 8/8 inches (1 inch or approx 25mm).

T5 LED Tubes: Smaller in diameter,these have a diameter of 5/8 inches (0.625 inches or approx 16mm).

T12 LED Tubes: They are the same length as T8,but have a larger 1.5 inch diameter (approx 32mm).

3.2 Types of LED Tube Replacements

Type 1: Work with AC230V directly (save energy and extend lifespan)

After removing the ballast and starter, make some simple changes to existing wiring and directly connect

LED tube to AC220V power supply.

This method can reduce the energy consumption of ballast itself, reduce failures caused by the ballast and starter,

and extend the service life of tube.

It can be divided into single-ended power and double-ended power feeding.

Type 2: Work with magnetic ballast

If the fluorescent tube uses a magnetic ballast, you can choose an LED tube that is compatible with a magnetic ballast

without changing the circuit. You need to replace starter with an LED starter.

It is divided into single-ended power and double-ended power feeding.

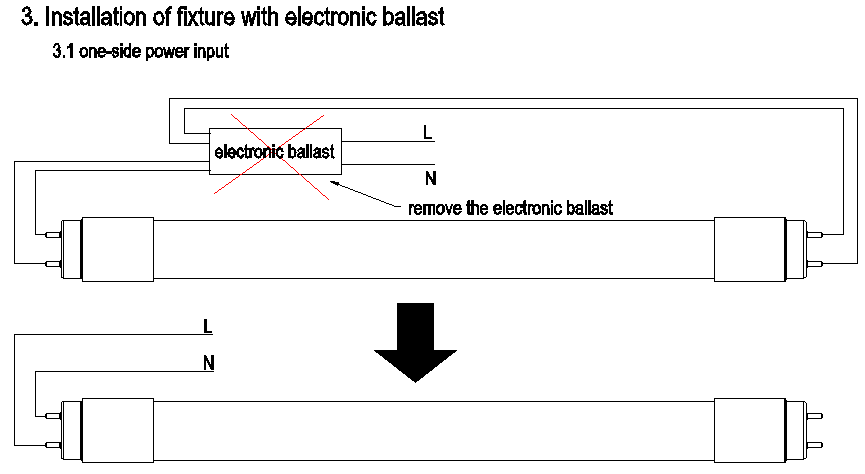

Type 3: Work with electronic ballast

If the fluorescent tube uses an electronic ballast, you can choose a LED tube that is compatible with a electronic ballast

without changing the circuit.

When purchasing LED tube, you need to confirm with the supplier which ballast are compatible. If they are not compatible,

the tube will not work properly.

It is divided into single-ended power and double-ended power feeding.

4. Preparation for Replacement

4.1 Safety Precautions

Turn off power at the breaker to avoid electric shock.

Wear safety gloves and goggles.

4.2 Tools and Materials Needed

Screwdriver

Wire cutters/strippers

Voltage tester

4.3 Understanding Wiring Configurations

Familiarize yourself with the existing wiring setup to ensure a smooth installation process.

Step-by-Step Replacement Guide

Single-ended power feeding: only the two pins on one end of the tube are used (one pin = live; one pin = neutral),

and the two pins on the other end are not electrically functional, and only used for holding the lamp in place.

Double-ended power feeding: the two pins on each side of the tube are the same polarity. Therefore,

the lampholders on one end of the tube must be connected to [neutral], while the other must be connected to [positive].

Type 1: Work with AC230V directly

Installation steps

1. Turn off power

Make sure the lights are powered off to avoid the risk of electric shock.

2. Remove the fluorescent tube and ballast and starter

3. Install LED light tubes

4. Power on test

Restore the power and check whether the LED light tube is working properly.

Type 2: Work with magnetic ballast

Installation steps

1. Turn off power

Make sure the lights are powered off to avoid the risk of electric shock.

2. Remove the fluorescent tube

3. Check magnetic ballast

Verify there is an magnetic ballast inside the light fixture and make sure it is working properly.

4. Replace starter with a LED starter.

5. Install LED light tube

6. Power on test

Restore the power and check whether the LED light tube is working properly.

Type 3: Work with electronic ballast

Installation steps

1. Turn off power

Make sure the lights are powered off to avoid the risk of electric shock.

2. Remove the fluorescent tube

3. Check electronic ballast

Verify there is an electronic ballast inside the light fixture and make sure it is working properly.

4. Check the starter (if have)

In electronic ballast systems, there is usually no starter. If there is a starter, refer to the manufacturer’s instructions

to determine whether it needs to be removed.Most electronic ballast-compatible LED tubes no need remove the starter.

5. Install LED light tubes

6. Power on test

Restore the power and check whether the LED light tube is working properly.

6. Troubleshooting Common Issues

Flickering Light: Check wiring connections and ensure compatibility.

No Light: Verify power supply and proper installation.

Dim Light: Ensure the LED tube is compatible with the fixture and ballast.

7.FAQ

1. Why should I replace fluorescent tubes with LED tubes?

LED tubes are more energy-efficient, have a longer lifespan, and provide better quality light compared to fluorescent tubes.

They also contain no hazardous materials like mercury, making them safer and more environmentally friendly.

2. Do I need to change the fixtures to install LED tubes?

It depends on the types of LED tube you choose:

Type 1: Work with AC230V directly

After removing the ballast and starter, make some simple changes to existing wiring and directly connect LED tube to

AC220V power supply.

Type 2: Work with magnetic ballast

If the fluorescent tube uses a magnetic ballast, you can choose an LED tube that is compatible with a magnetic ballast

without changing the circuit. You need to replace starter with an LED starter.

Type 3: Work with electronic ballast

If the fluorescenttube uses an electronic ballast, you can choose a LED tube that is compatible with a electronic ballast

without changing the circuit. You should choose the LED tube is compatible with the ballast.

3.How do I know if my fluorescent fixture is compatible with LED tubes?

Firstly you should check and know what type of electronic ballast or magnetic ballast for existing fixture.

For magnetic ballast, most LED tubes on the market are compatible.

For electronic ballast,when purchasing LED tube, you need to confirm with the supplier which ballast are compatible.

If they are not compatible, the tube will not work properly.

4. Are LED tubes dimmable?

Not all LED tubes are dimmable. You need to check the product specifications to ensure the LED tube you choose

supports dimming.

5. How do I dispose of old fluorescent tubes?

Fluorescent tubes contain hazardous materials like mercury and should be disposed of according to local regulations.

Many regions have recycling programs or designated drop-off points for proper disposal.

6. Are there any incentives or rebates for switching to LED tubes?

Many utility companies and government programs offer incentives or rebates for switching to energy-efficient lighting,

including LED tubes. Check with your local utility provider for available programs.

7.How do you wire LED tubes?

Wiring LED tube lights involves either a direct wire setup or using a compatible magnetic and electronic ballast.

For a direct wire setup, first, remove the existing fluorescent ballast from the light fixture, then connect the live

or neutral wire to the end of the fixture, adhering to your LED’s wiring configuration—either single-ended or

double-ended. Ensure all connections are secure and that no wires are exposed before testing the light to

confirm it works correctly.

8.What is Single-ended and Double-ended LED tube?

Single-ended LED tube lights are designed to receive power from one end of the tube. All electrical connections,

including live and neutral wires, are made at one end, requiring non-shunted sockets. This setup often simplifies

wiring but requires more caution during installation to ensure the correct end is powered.

Double-ended LED tube lights receive power from both ends, with one end connecting to the live wire and

the other to the neutral. This arrangement is generally considered safer and easier to install, especially

when retrofitting existing fluorescent fixtures, as it aligns with the wiring setup of many traditional fluorescent fixtures.

9.What are the differences between single-ended and double-ended LED tube?

The main difference between single-ended and double-ended LED tube lights lies in their wiring requirements

and installation safety.

Double-ended tubes are typically easier to install and considered safer, as they distribute the electrical load

across two ends of the tube, whereas single-ended tubes centralize all electrical connections at one end,

which can pose a higher risk during installation if not handled properly.

10.Will LED tubes can work in fluorescent fixtures?

Yes, LED tubes can work in fluorescent fixtures, but it depends on the type of LED tube light and the existing

fixture’s configuration. When converting to LED, check the specific requirements and compatibility of the

LED tubes with your existing fluorescent fixtures to ensure proper installation and operation.

11.What are color temperatures option of LED tube?

LED tube light can be made with different colour temperatures as below:

3000K – Warm white light has a yellowish tint, creating a cozy and comfortable feeling. Ideal for homes, restaurants, hotels, and bedrooms where you want a warm and inviting atmosphere.

4000K – Natural white light is close to daylight, not too warm or too cool. Perfect for offices, kitchens, and workspaces where you need clear and soft lighting.

5000K – Pure white light is very bright and clear, similar to midday sunlight. Used in commercial spaces, retail stores, garages, and photography studios for bright and efficient lighting.

6000K – Cool white light has a bluish tint, appearing very bright and crisp. Suitable for industrial areas, hospitals, laboratories, and parking lots where high brightness and clarity are needed.

12.How do you wire LED tubes without ballast ?

After removing the ballast and starter, make some simple changes to existing wiring and directly connect LED tube

to AC220V power supply.

8.Expert Tips and Advice

Always check compatibility before purchasing.

Follow safety guidelines to prevent accidents.

9. Conclusion

9.1 Recap of Key Points

Upgrading to LED tubes offers energy efficiency, cost savings, better light quality, and environmental benefits.

9.2 Encouragement to Make the Switch

Making the switch to LED tubes is a smart investment for both your wallet and the environment.

Request A Quote for Your LED Tube Projects!

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email with the suffix “@reapway.com”.