3:Wickes Warehouse Lighting Transformation—Tripling Illumination and Reducing Energy Costs by 40%

1) Introduction

Project Name: Wickes Warehouse, Longdon, UK

Wickes Group plc, a leading UK-based home improvement and garden center retailer, operates over 230 stores across the country. They specialize in providing materials and supplies for homeowners and the building trade.

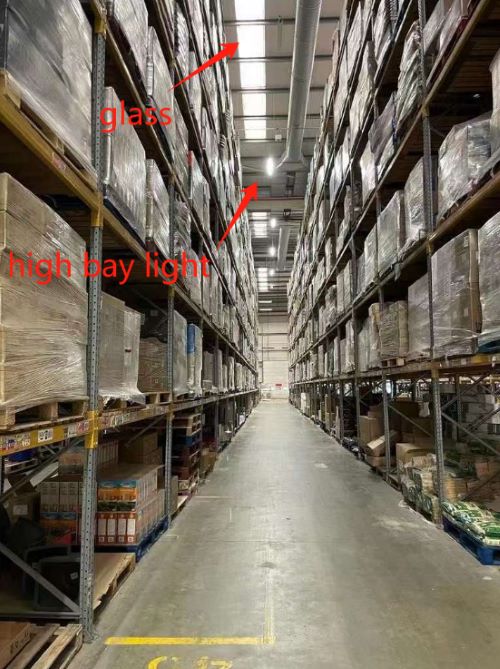

This case study highlights the successful lighting upgrade at one of Wickes’ warehouses (1100m2) in Longdon, UK. By replacing outdated lighting with Reapway Apex LED Linear High Bays, the warehouse not only tripled its illumination but also reduced

energy consumption by an impressive 40%.

Let’s dive into the details of how this lighting transformation was achieved.

2) Setting the Scene

Before the upgrade, Wickes Warehouse faced a significant challenge. The facility relied on 250W Metal Halide lamps (80LM/W), which

provided uneven lighting and lead to high energy consumption. The average illumination was only 50 lux, creating a less-than-ideal working environment and affecting both worker productivity and operational costs.

Faced with these issues, Wickes sought a lighting solution that would improve visibility, reduce energy usage, and enhance the overall warehouse operation.

3) Results Overview

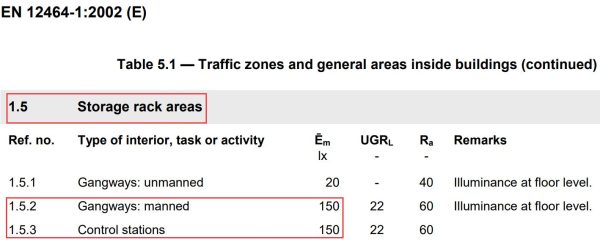

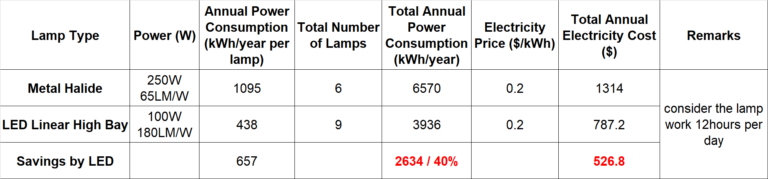

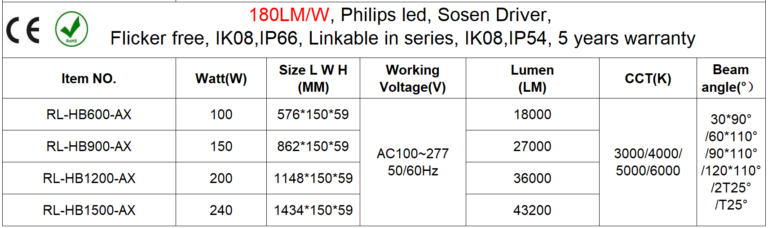

Switching to Reapway 100W 180LM/W Apex LED Linear High Bays had an immediate and transformative impact. The average illumination increase to 150 lux, which greatly enhanced the working environment.

Additionally, energy consumption dropped by 40%, leading to an annual electricity savings of 2634 kWh, or approximately $526.8.

Key Outcomes for One Wickes Warehouse:

1: Illumination increased to 150 lux, significantly improving visibility in storage rack areas and enhancing worker safety.

2: Energy savings of 40%, reducing overall operational costs.

3: Annual savings of 2634 kWh and $526.8 in electricity costs.

4: Uniform lighting across the entire shelving area eliminated blind spots, contributing to a safer and more efficient workplace.

4) How It Was Done

The lighting transformation at Wickes Warehouse began with a comprehensive assessment of the existing system. Poor illumination and high energy consumption were identified as major issues.

After careful evaluation, the Reapway 100W Apex LED Linear High Bays were chosen for their superior brightness and energy efficiency. These LEDs provided consistent, uniform lighting throughout the shelving area, eradicating blind spots

and enhancing safety. The upgrade not only improved visibility but also fostered a more comfortable and productive work environment, ultimately boosting operational efficiency.

5) Customer Reviews

James Anderson, Project Manager at Wickes Warehouse:

“Switching to Reapway LED Linear High Bay lights has improved our warehouse in Longdon. The even lighting has

eliminated dark spots and boosted efficiency. The energy savings and durability of the LEDs have also helped

lower our costs. Installation was easy, and with little maintenance, we’re already seeing great returns on investment.”

6) Conclusion

The lighting upgrade at Wickes Warehouse has been a success, tripling the light levels and reducing energy use

by 40%. This case shows that the right lighting can improve efficiency and lower costs.

Inspired by this? Switch to Reapway LED lighting and enjoy similar benefits in your own facility.